Volatile Organic Compound Regulations

Reducing Volatile Organic Compounds (VOCs) in the Petroleum Sector

Max Jantz, Regional Field Engineer

New Regulation Enforcement: Are You Prepared?

Volatile organic compounds or VOCs are human-made chemicals that are often components of petroleum fuels. An ongoing regulation enacted under the Canadian Environmental Protection Act, 1999, SC 1999, c33 was proposed to reduce the emission of VOCs, specifically in the Petroleum sector. The sector includes:

- 18 Petroleum Refineries

- 6 Upgraders

- 2 Petrochemical Facilities

These facilities are required to adhere to the requirements of the regulations, which include, but are not limited to:

- LDAR (Leak Detection and Repair)

- Equipment Component Requirements

- Fence line Monitoring

- Reporting

On January 1, 2023 sections 11-16 came into enforcement. While every section is important, this blog post focuses on sections 13 and 15 and how your local fluid system experts can assist you with the added responsibilities.

Section 13: Sampling Systems

Section 13 outlines criteria that must be met regarding onsite sampling system design.

Sampling systems in the petroleum sector have come a long way from the once common spigot and pail method. Those archaic methods of sampling led to a whole host of problems and are not acceptable practices in the industry anymore.

An operator pulling a sample using those outdated techniques is exposed to whatever process media they’re sampling. Spills and vapour releases are also very common when your sample bomb is open to the atmosphere.

On top of the health challenges of those prior sample methods, quality concerns were also an issue. Representative samples are easier for lab technicians to analyze and allow for more accurate process changes to be conducted if the facility feels they’re creating an off-spec product.

These changes are outlined in the regulation, which states that the designs of onsite sampling must include closed purge, loop, and vent systems. This means the sample is contained in a closed container and any process media not contained in the volume of that sample is either returned to the process, or disposed of, re-used, or treated.

These best practices are all integrated in Swagelok® Grab Sampling Systems. Our pre-designed and custom grab sampling systems can bring a site up to regulation specifications. On top of the physical systems, our sampling subject matter experts can be leveraged to advise on Swagelok® Custom Solutions to ensure the most complex samples are given the attention they require.

These best practices mitigate both the health concerns and quality issues facilities are plagued with when still using out-of-date methods. Our sampling experts can visit your site and commission new sampling systems to ensure the operator is properly trained on techniques that lead to accurate, repeatable, and safe sampling.

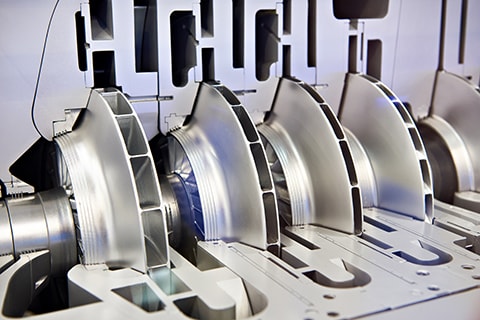

Section 15: Centrifugal Compressors

The regulation states every centrifugal compressor must be equipped with a mechanical seal that has a barrier fluid system.

This seal system must:

- Be operated with a fluid that is always higher pressure than the stuffing box pressure.

- Have a degassing reservoir that is connected by a closed vent system to the process.

- Be equipped with a purge system that purges the barrier fluid into the process and prevents releases of VOCs.

This could cause existing onsite systems to be refurbished or even replaced. Much like the sampling requirements, this section outlines the need for experienced individuals to investigate, propose, and implement solutions.

Our seal support solutions offerings are guided by API 682 and provide excellent starting points for any onsite equipment that requires new seal support systems.

Our Custom Solutions department is also capable of tackling more complex systems that go beyond our robust application solutions offerings.

Our team of subject matter experts is here to support you and your facility as you navigate the new VOC regulations.

Contact us with your VOC regulation or application questions

Useful Reference Links:

- EPA: What are volatile organic compounds (VOCs)?

- Bennett Jones: Federal VOC Regulations for Petroleum Sector

- Government of Canada: Statutory Order & Regulations (SOR/2020-231)

- Swagelok: Minimize the Costs of Fugitive Emissions with Low-E Valves

subscribe to the swage talks blog